Everything You Need To Know About Sorting And Washing Of HDPE Products

HDPE, stands for High density polyethylene, are the products that often require sorting in large organizations. Polyethylene is one of the most common polymers used for making plastic that requires HDPE sorting. It has many names: LDPE (Low-Density Polyethylene), MDPE (Medium Density Polyethylene), and HDPE (High-Density Polyethylene). Other variants include PETG, PE-LD, PE-HD, and PP-H. PE recycling usually uses reclaimed plastic from other sources in manufacturing, such as bottling and packaging.

● Sort Out The Plastic

As we all know, plastic is one of the best materials used in packaging and storage. But these containers must be properly cleaned to avoid any damage. There are many ways to do so and each one has its advantages and disadvantages. In order to achieve great results, you have to figure out which method is perfect for your facility’s needs.

● Know The Right Recycling Products

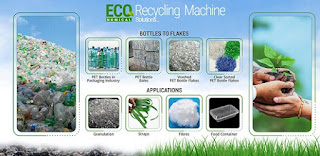

When people think of a recycling center, they most likely picture plastic bottles and aluminum cans. These are among the most common products that can be recycled, but it’s easy to forget that there are many other types of plastic available. Your local recycling center or sorting facility may have accepted it in your neighborhood—but don’t assume so! Make sure you check before tossing any plastic items into your recycle bin.

● Choose The Best Sorting Machine For Plastics

HDPE Sorting machines are used to separate materials based on their size, weight, color,and purity. Plastics are an important type of material for sorting because there are so many different types available. Plastic sorting machines can be useful in factories where plastic parts and products are manufactured.

Conclusion

When it comes to hdpe washing lines and sorting, there’s no one-size-fits-all method. There are multiple factors to consider when determining which system will work best for your organization. By having a good understanding of all of your options, you can choose systems that will get your products clean in a way that fits into your production workflow.

Comments

Post a Comment